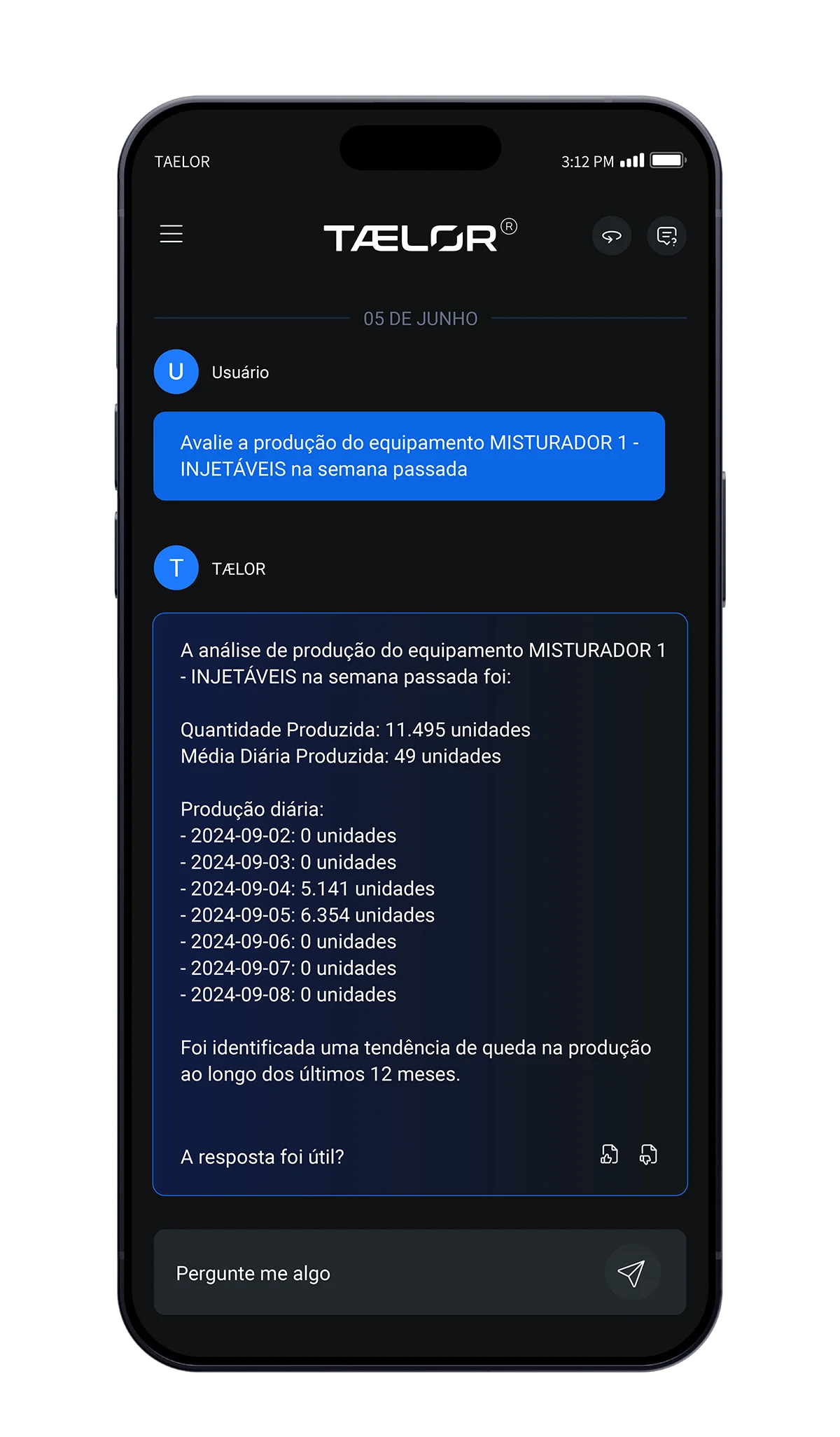

Make Decisions and Analyze Data in Record Time with Your AI Management Partner

TÆLOR is Cogtive’s AI solution, offering precise, real-time insights to help you manage the factory floor from end to end.

Maximize Your Operation's Potential with a Virtual Engineer on Your Phone

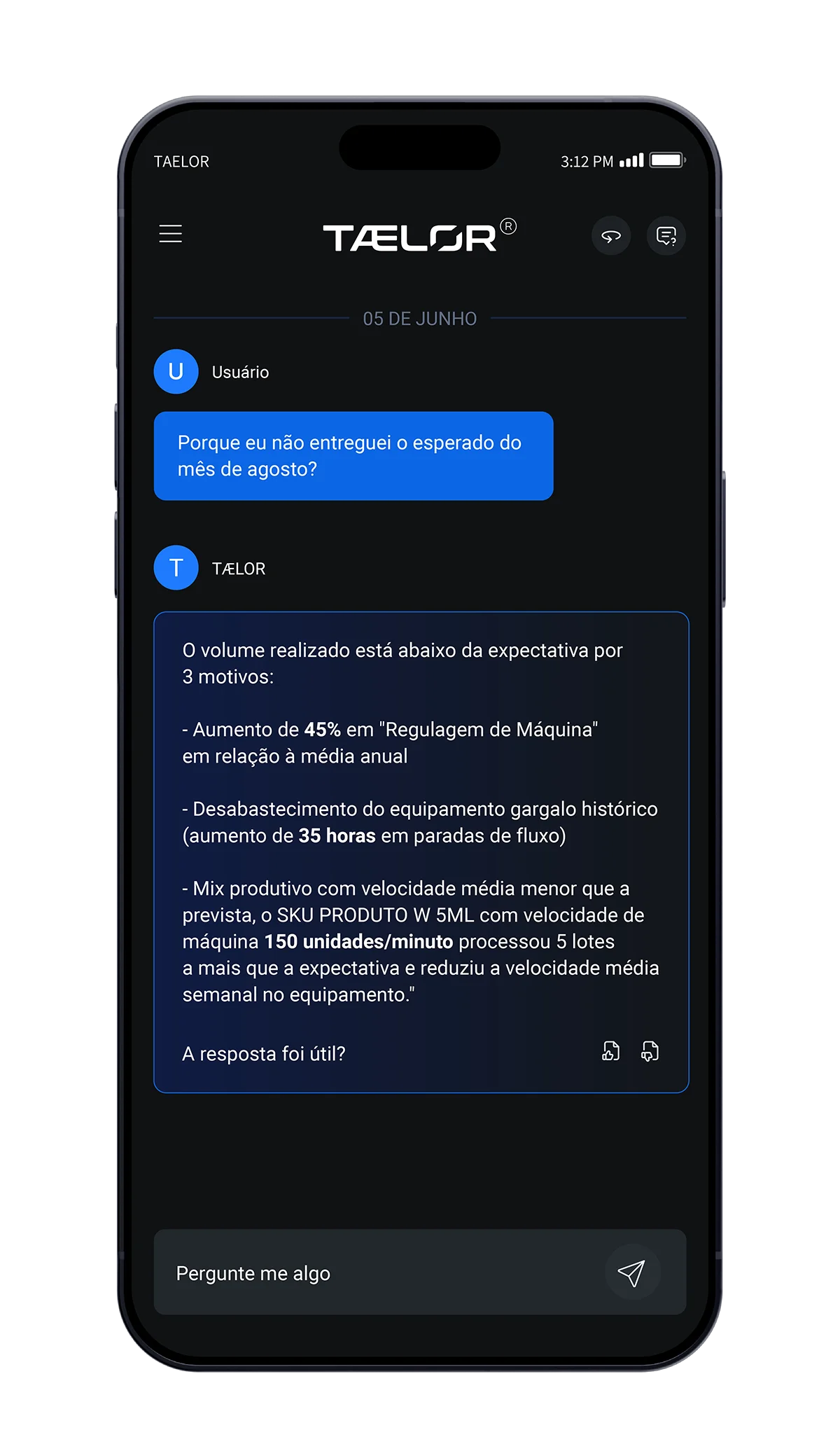

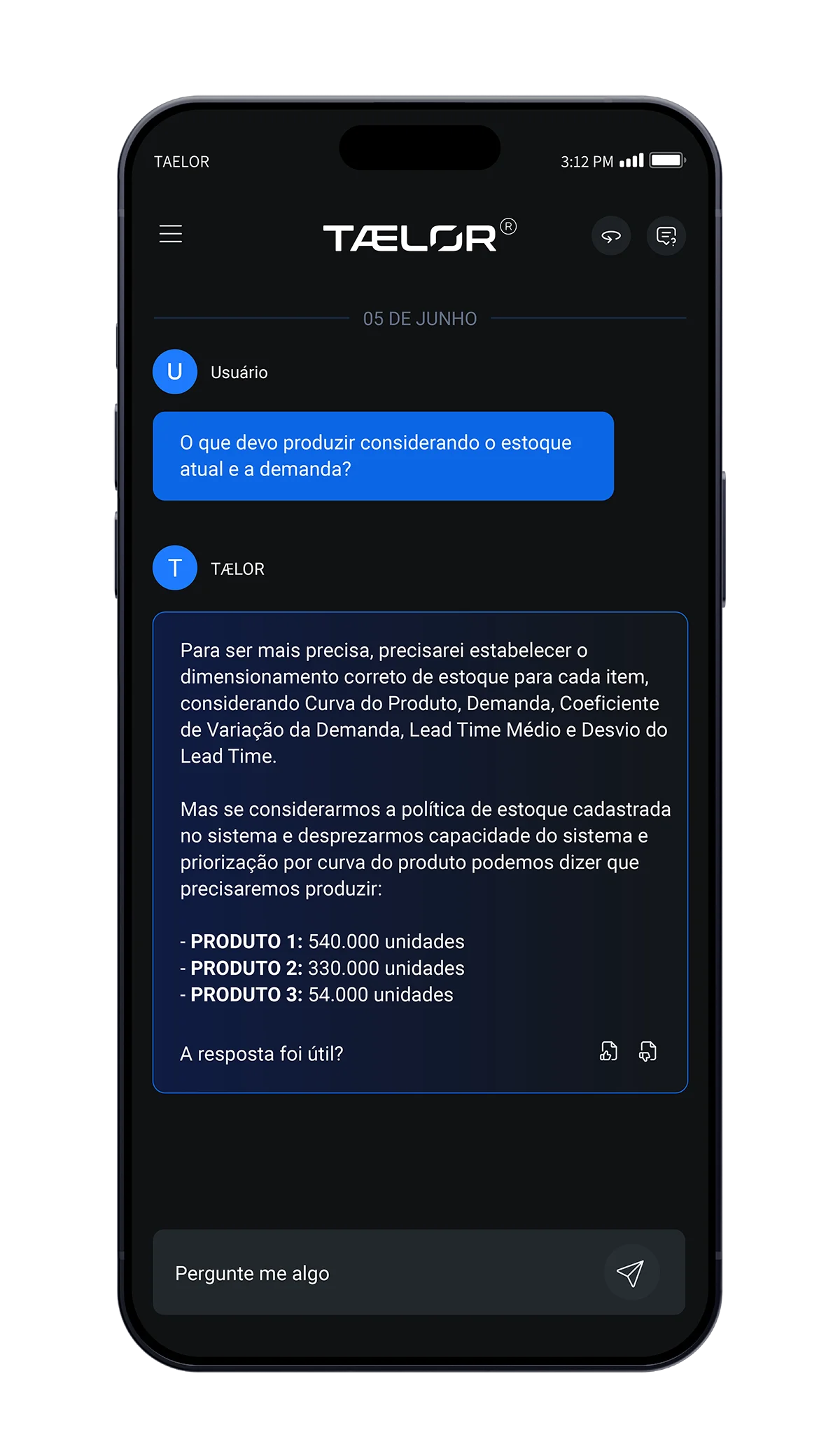

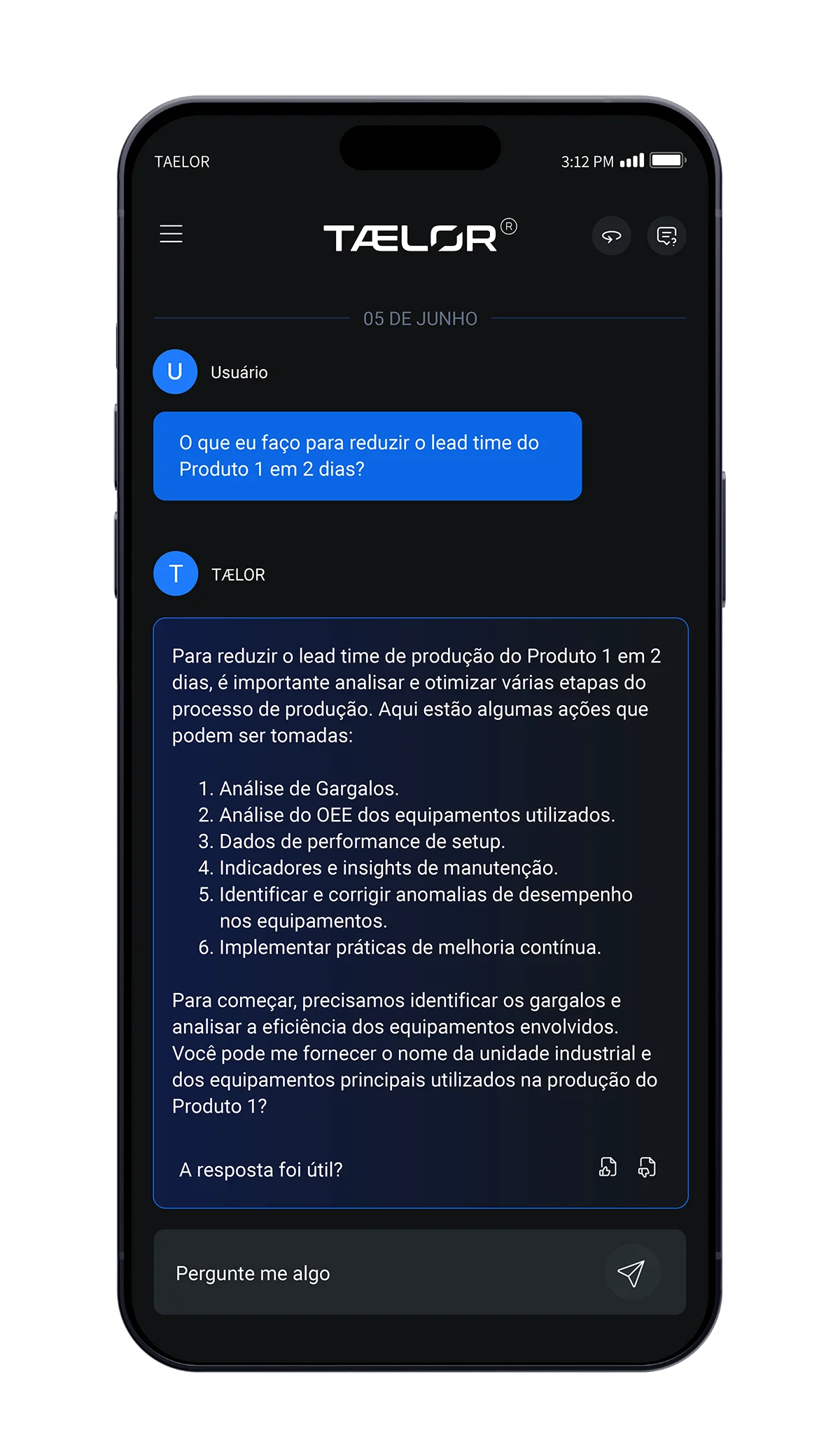

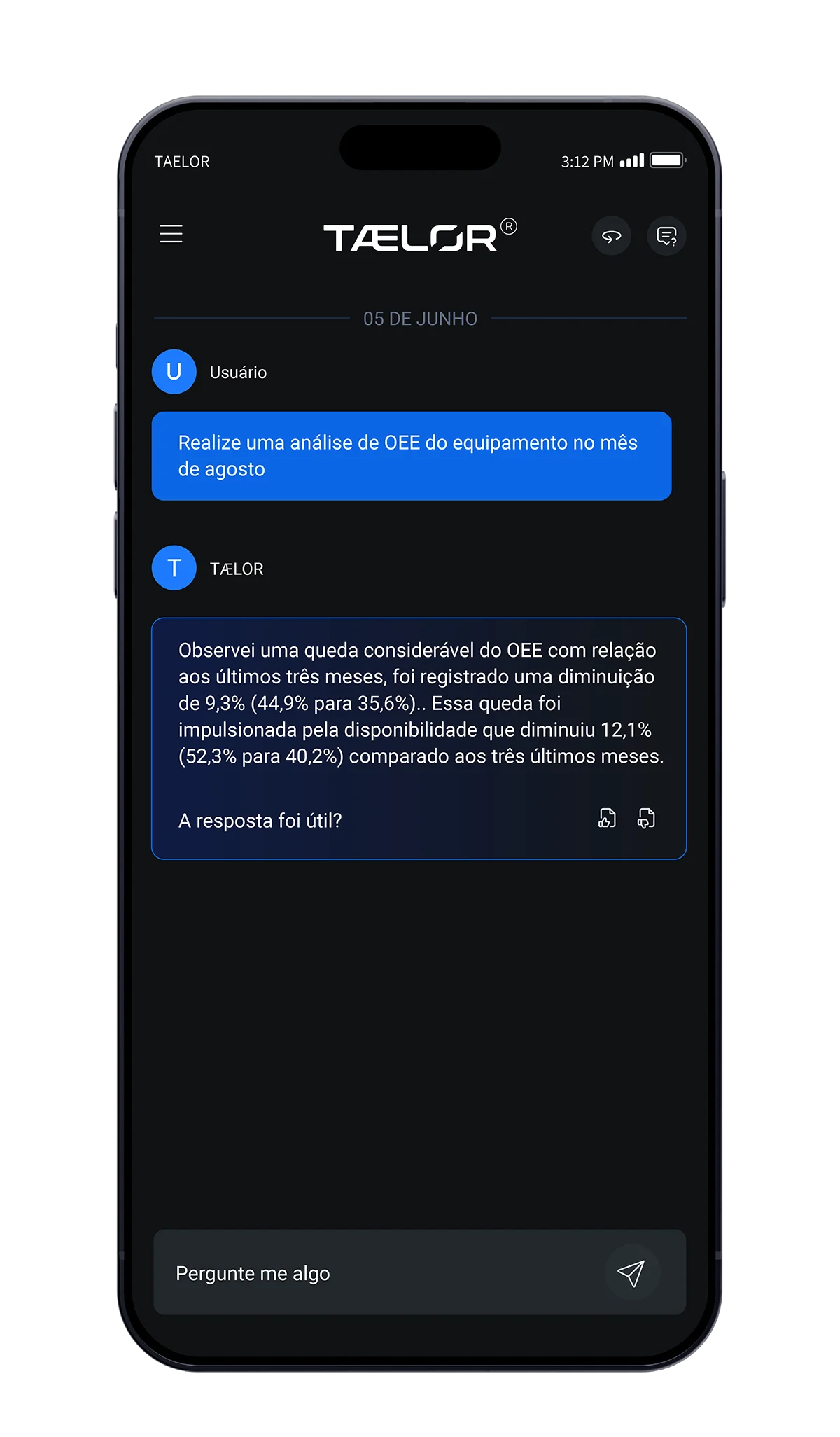

Access your operations with ease, without the need to allocate extra resources for data analysis.

Get answers to a wide range of questions across Production, Planning, Maintenance, and Operational Excellence, with data-learning capabilities that improve over time.

All processed data is encrypted to ensure the privacy of your sensitive operational information.

Achieve up to 12x ROI in Just 1 Year

We’ve created a comprehensive guide to show you how our clients have achieved up to 12x ROI in a single year. The financial and operational benefits delivered by Cogtive unlock savings that can fuel future investments and plant expansion.

Your Right-Hand Ally for Managing the Factory Floor

Gain instant insight into every key performance indicator across your operations. Using TÆLOR is as simple as starting a conversation—just ask a question, and you’ll receive answers with the precision and depth of an entire team, straight to your phone.

Cogtive is the daily partner for Production, PPC, and Operational Excellence teams.

Automatically collected data: Eliminate spreadsheets and papers that may cause errors with a 100% digital platform.

Automatically collected data:

Eliminate spreadsheets and papers that may cause errors with a 100% digital platform.

Ready-to-use indicators from day one: Receive the first machine data the moment Cogtive is activated in your operation.

Ready-to-use indicators from day one:

Receive the first machine data the moment Cogtive is activated in your operation.

More efficient management with less decision-making time: Speed up Gemba and Heijunka meetings with consolidated data on a single platform.

More efficient management with less decision-making time:

Speed up Gemba and Heijunka meetings with consolidated data on a single platform.

Comprehensive and flexible for your operation type: Cogtive uses up to 3 different data collection methods to adapt to your needs: automatic, semi-automatic, and AI Vision.

Comprehensive and flexible for your operation type:

Cogtive uses up to 3 different data collection methods to adapt to your needs: automatic, semi-automatic, and AI Vision.

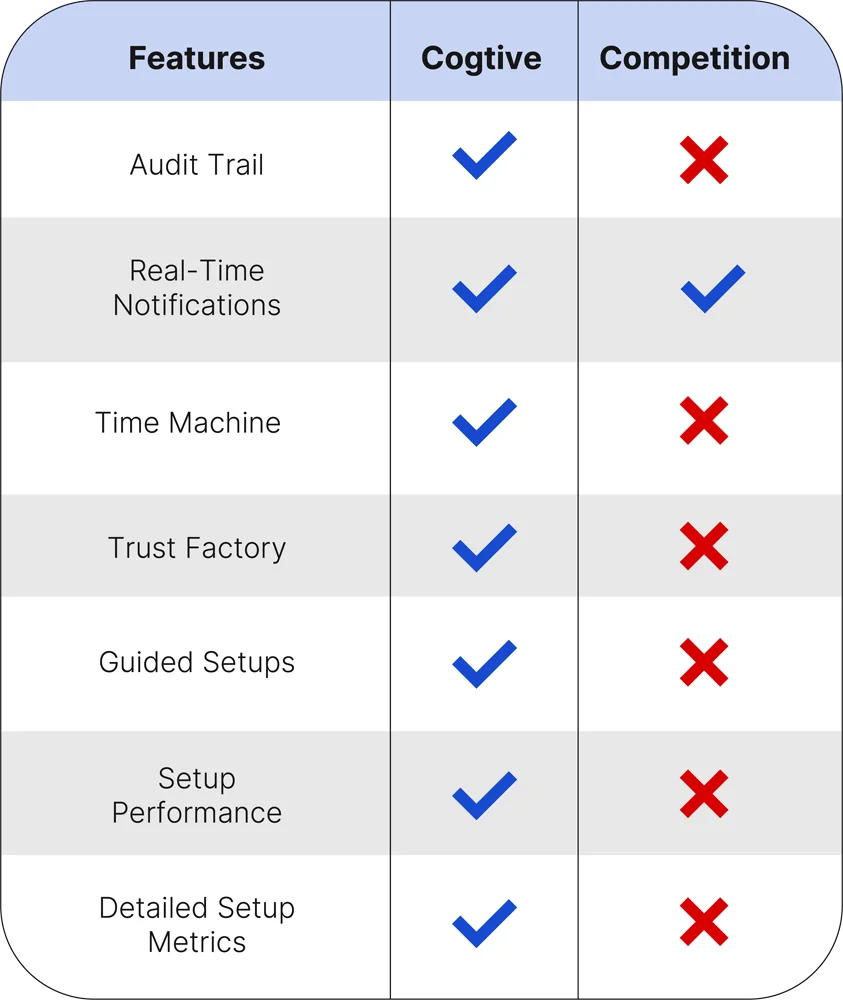

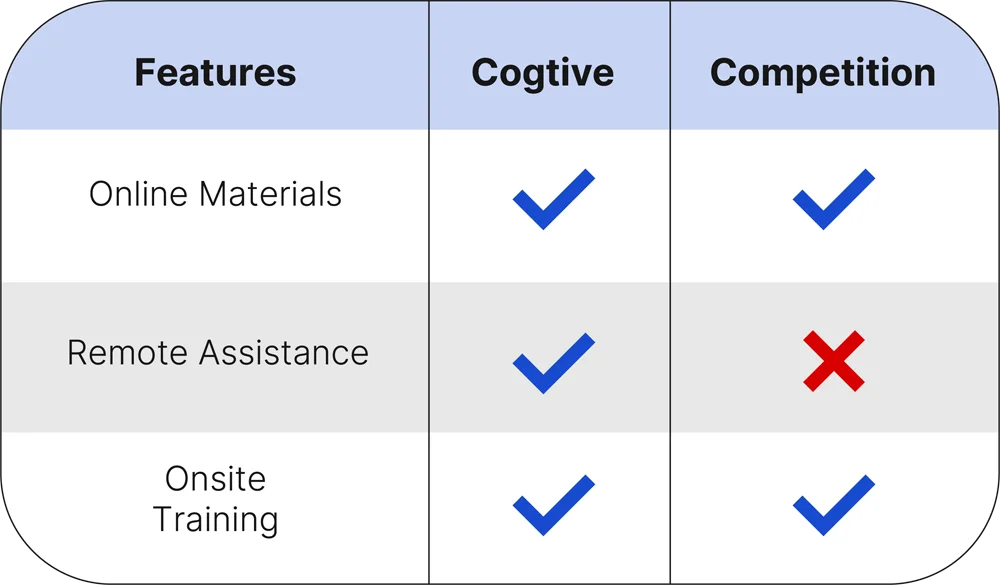

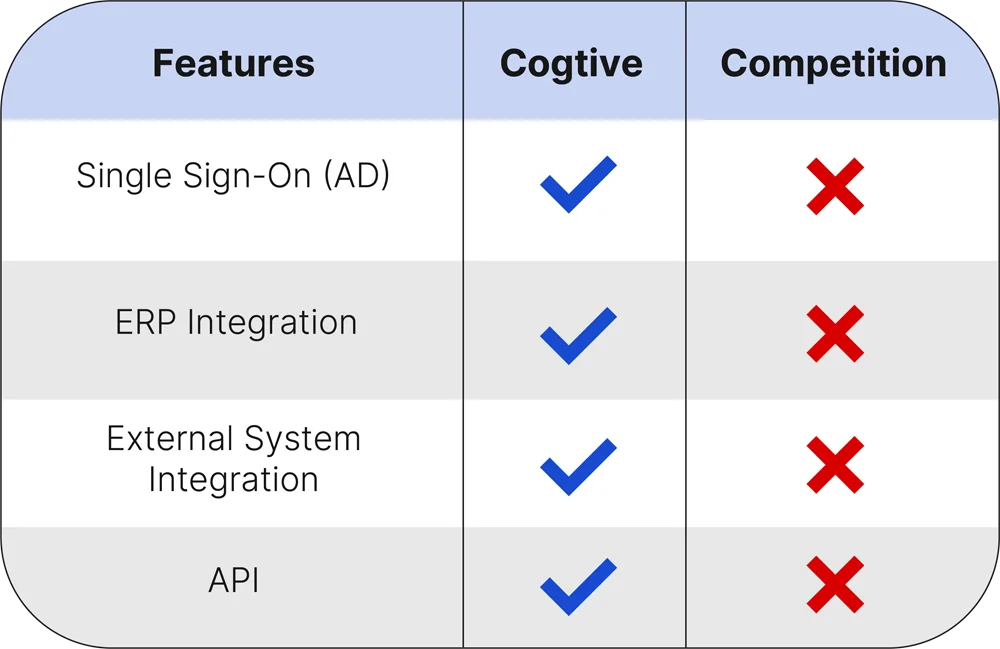

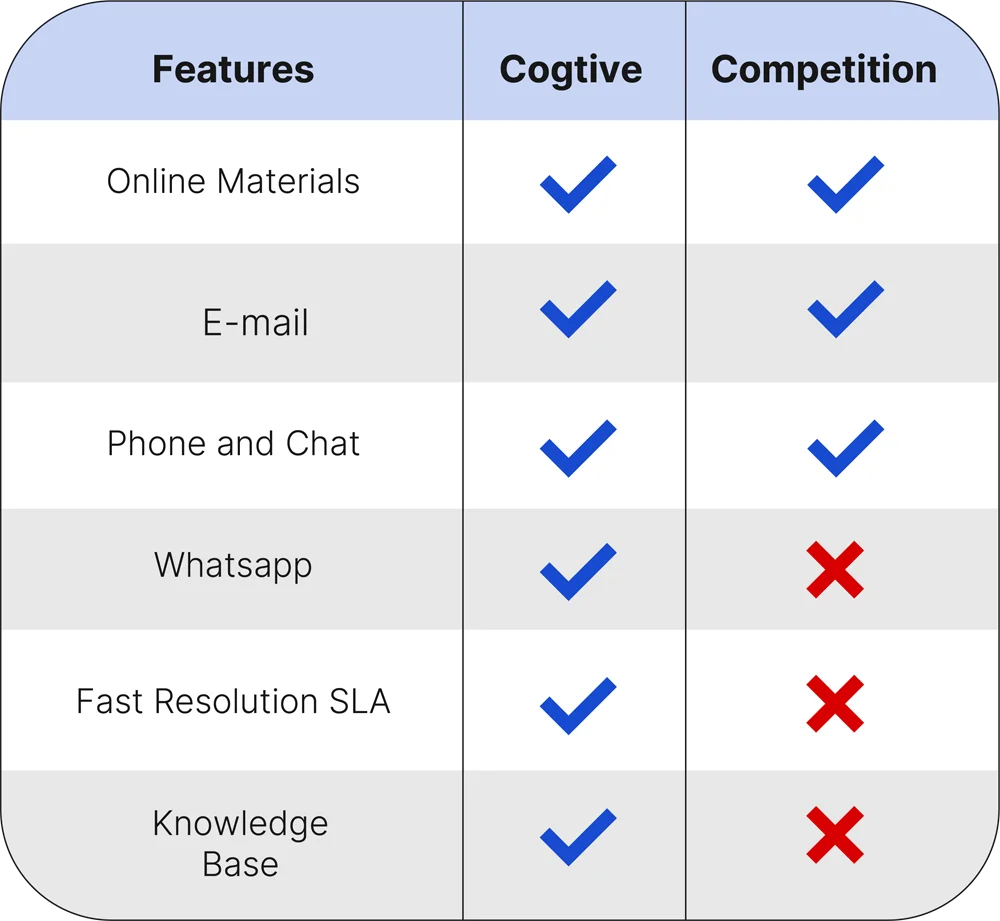

Benefits and Advantages

Success stories

Learn how our clients achieved results with Cogtive.