Manufacturing Excellence

Cogtive is the leading end-to-end platform for managing industrial production, enabling the analysis of equipment efficiency, production flow, bottlenecks, and inventory levels.

Trusted by companies worldwide

Industrial management tools for Production, PPC and Operational Excellence teams

Talk to our experts and learn about the system!

Schedule a meetingResults achieved with our platform

$300M

in savings for our clients

30%

increase in production capacity

50%

reduction in

lead time

15%

increase in equipment

availability

12x

return on

investment

12 months

payback per

industrial unit

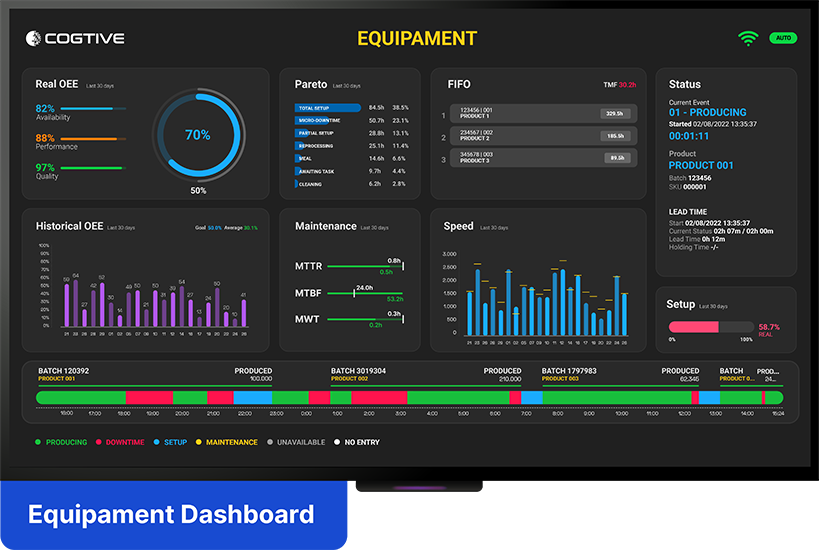

Monitor your production performance in real-time

Track OEE, FIFO, and equipment status. View downtime reasons, maintenance indicators (MTTR, MTBF, MWT), and desired setup times.

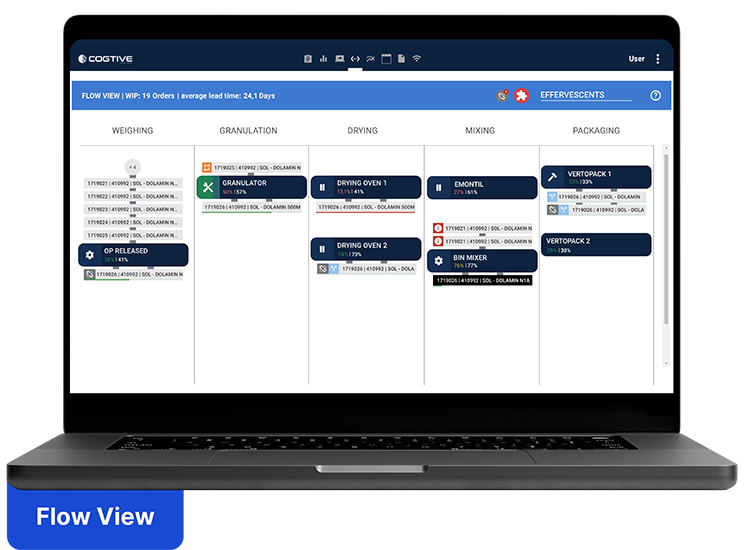

Track batch progression

Get insights into batch movements with predictability for each phase, equipment status, control of holding time, and real-time notifications for selected batches.

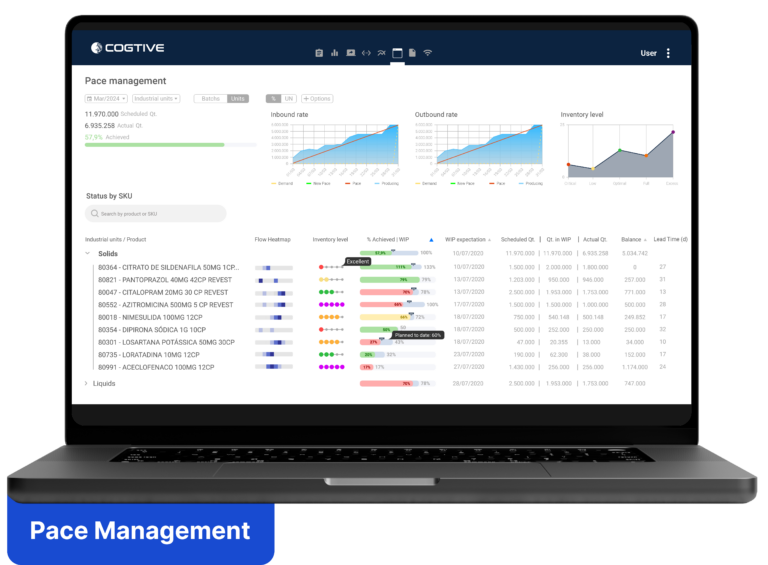

Ensure delivery predictability

Know if the batches in process will be enough to meet your targets. Visualize batch positions in the flow, view production fulfillment, and monitor stock levels by SKU.

Achieve the fastest setups in the market

Standardize your setups with a complete guide. Monitor adjustments, get an overview of setups for resource allocation, track specific equipment status, and view availability with the Ramp-Up report.

Monitor productivity and optimize resources

IA Vision combines data collection via cameras and video recognition to analyze workstation images in real-time, enabling resource optimization.

Optimize decisions with a virtual engineer

TÆLOR is the only AI that, with a simple command, analyzes all data and provides the best strategy to optimize your production.

Learn how we can boost your production capacity

Request a demoArtificial intelligence serving your management needs

TÆLOR is Cogtive’s revolutionary AI, developed to transform shop floor management. With precise and relevant information, TÆLOR empowers strategic decision-making, directly impacting the efficiency and productivity of the manufacturing sector.

Overcome the lack of resources and time for data analysis:

Using TÆLOR is extremely simple. Ask questions directly from your smartphone and get answers based on data collected and analyzed by the Cogtive system, fully integrated with your shop floor.

What our clients say

Still have questions?

FAQHere you will find the answers to the most common questions about our platform,

from features to conditions of use.

What does COGTIVE do?

COGTIVE is an IoT and A.I.-based MES+MOM software for optimizing processes and increasing productivity in factories and industries. The solution collects data, processes it, and provides a clear digital view of the factory floor for managers and production line operators. Using artificial intelligence and video recognition, COGTIVE can identify improvement opportunities and find the right person with the right role to solve problems before they become relevant.

Why do I need a solution like COGTIVE?

If you want to increase your factory’s efficiency, reduce downtime, improve production rates, optimize labor use, and achieve your factory’s full capacity, COGTIVE will help you.

How long does it take to implement COGTIVE?

COGTIVE is a plug-and-play system, meaning you just need to start collecting data and upload the base (equipment, products, and cycle times/speeds), and the information will start to be generated. It’s simple, fast, and easy.

Can I install COGTIVE on any equipment?

Yes, the system can be implemented on any type of equipment or production line. It can be used for discrete/continuous production equipment, where sensors can be used to count approved and rejected products (regardless of the line size), batch equipment (such as tanks, mixers, coaters, and reactors) where it’s possible to measure the process duration/recipe, or even manual lines where there’s no process automation.

What are the hardware investments required to use COGTIVE?

Data collection can be done manually, without hardware investment, or with the use of sensors connected to an IoT that communicates with the software through a simple tablet – which is not necessarily provided by us, so it’s possible to reuse tablets from the commercial area or other areas of the company, which ends up being a great saving.

How long does it take to have good enough data to be analyzed?

It all depends on the degree of commitment and dedication of the team involved. In cases where there is a small dedicated team (one person is enough for small companies) for implementation, data collection, and team training, it’s possible to have reliable data around 30 days after the implementation start.

To speed up this entire process, we provide and assist in the execution of a step-by-step implementation process – based on the best practices of our customers and our market experience – which ranges from Database Consolidation to Indicator Evaluation and Success Case Creation.

My company is small and has few equipment, can I implement COGTIVE?

Certainly! COGTIVE works with small to large companies since the contract value varies according to the number of contracted equipment! Contact us and request a quote, you will be surprised!

Is COGTIVE an OEE measurement system?

No, COGTIVE is much more than that! In addition to detailed information on OEE and its derivatives, its main function is to assist leadership in decision-making on the factory floor, with flow management made possible by Flow View (our digital twin). That is, the system provides in real-time:

- Lead Time information;

- WIP Control;

- Equipment queue management;

- Ideal sequencing of batches;

- Anticipation of Holding Time problems of batches;

- Equipment effectiveness;

- Improvement insights through our artificial intelligence, Taelor, and much more.

I already have a solution for my OEE. Does COGTIVE add value?

Yes, COGTIVE adds a lot of value to your OEE. While other OEE solutions focus on individual machines, COGTIVE provides a holistic view of the production process, allowing you to focus your efforts on bottlenecks and leverage the full potential of your factory. Additionally, our solution incorporates insights from our AI, TÆLOR, unique indicators for setup performance, an exclusive holding time management system, and maintenance-related features.

We have never worked with OEE in our company, can we still implement the system?

Absolutely! The COGTIVE team has experts in Flow Management and Process Performance who can provide quick and practical qualification for your team.

Our calculation metrics and indicators are very different from the entire market, can we still use COGTIVE?

COGTIVE allows the user itself customization of parameters and indicators to fit your company’s needs. For example:

-

“In our OEE calculation, we exclude Meeting/Training events.”

It is possible to select the events that were included or excluded from the OEE calculation. -

“We calculate MTBF, MTTR, and MWT maintenance indicators considering only corrective maintenance.”

It is possible to select the events that were included or excluded from the maintenance indicators calculation. -

“We have several types of events different from the market.”

It is possible to register as many events as necessary. -

“We have several alternative equipment to process the same product.”

It is possible to register alternative equipment on product routes. -

“We have an average meal time indicator, can I create this indicator?”

Yes! It is possible to create custom indicators quickly and easily, without the need for COGTIVE team support.

-

“In our OEE calculation, we exclude Meeting/Training events.”

How can the top and middle management utilize the system?

COGTIVE consists of various indicators and dashboards that aid in quick decision-making and understanding of your factory’s capacity. Furthermore, the Heindall system evaluates data and identifies inconsistencies and anomalies, enabling corrections and greater confidence in the analyzed data. In other words, it facilitates decision-making using increasingly reliable numbers.

In addition, lots with priority delivery or under surveillance can be favored by the user, allowing them to receive real-time information via their phone/email. The Manager/Director will no longer need to send 10 messages or make 10 calls to know the status of products or equipment; all this information will be in their hands.

Is it possible to export data to Excel?

Yes, all data contained in the system is exportable. All COGTIVE reports are exportable to Excel. The reports contain the main calculations, module results, and registration information.

Is it possible to connect COGTIVE to my ERP or BI?

Yes, COGTIVE has an open public API (restful) allowing any ERP and BI to be integrated with minimal effort.

How does support work?

The customer support area will be responsible for providing technical support and assistance to users of the software-as-a-service platform. Support uses various communication channels such as email, chat, WhatsApp, and phone to meet customer demands.

In addition, support team members can provide training, documentation, and self-service resources to help users maximize the use of the SaaS solution.

Support hours are from 8:00 am to 6:00 pm, Monday to Friday, except holidays.

Is your question not listed in our FAQ?

We understand that your choice of management software is important and requires careful consideration.

Please don’t hesitate to contact our support team to answer any additional questions you may have.